thzl@shth.com.cn

021-34679131

021-34679132

Mainly applicable to plastics, it can accurately control the temperature of plastic forming mold to shorten the molding cycle, accelerate product shaping; The series uses the principle of cold and heat exchange to cool, can quickly cool down, temperature control stability.

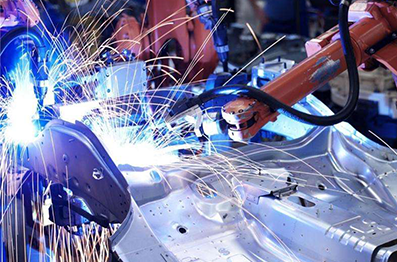

Electrodes, welding furnaces and cutters all need to be cooled. Such as large and medium-sized welding electromechanical pole welding nozzle cooling, gold, silver hand finishing processing of electric furnace cooling. Usually small to medium-sized chillers require an internal and external circulating water pump system or enclosed waters. For more information, please contact Taiheng Technology or Business

Detailed content>Metal thermal plating, surface ultrasonic cleaning, chemical surface and electrochemical surface treatment, all need the cooling and cooling of chillers, especially metal plating chillers, most of them need corrosion-resistant outer boxes and corrosion-resistant circulation systems, the main components of materials are chemical plastics, 304, 316 and other corrosion-resistant materials. For more information, please contact Taiheng Technology or Business

Detailed content>Laser cutting, cutting machine tools (machining center, lathe, milling machine, drilling machine, etc.) require the tool or spindle to turn at high speed to generate heat, in the cutting process also produces a large amount of heat. In these machine equipment, it is necessary to use chiller cooling, such as spindles, cutting fluids, lubricants, hydraulic oils, electronic cabinets, etc., to improve product quality and extend tool life. For more information, please contact Taiheng Technology or Business

Detailed content>